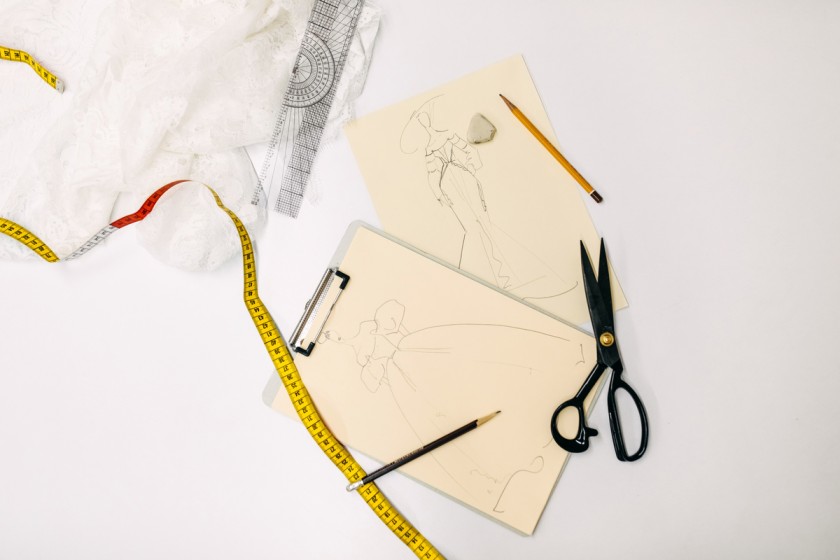

Pattern and Garment Technology: A Case Study

The need for Pattern and Garment Technology

An art supported on pattern designing with templates is termed pattern technology. These are made from articles of clothing and craft items that can be sewn. The method of pattern making helps come out with imagination from the designers sketching to the real product. The term pattern and garment technology refers to the technical issues dealt with by designers and technologists working in the field of pattern technology. Once the designers complete their work with garment designing, technical designers start with the preparation of the pattern of the garment. A garment-making process is an amalgamation of multiple small processes. Every garment should be aesthetically appealing, fitting correctly, and drape magnificently, all of which depends on the garment-making process.

For regular use, garment templates are created out of paper or cardboard templates that have been pre-cut. You can cut or trace your desired design for better markings and precise cuts of the fabrics. You'll cut or trace your required style of the fabric part by part, such as the body, legs, torso, shoulders, etc. and assemble them to sew them accordingly.

From medieval times, sewing has been done manually or on ancient looms. Pieces were ergonomically delved into rectangular pieces to attenuate wastage. As advancements were introduced, tailors and garment designers started cutting precise body-shaped pieces for more accurate stitching. Customization was the sole demand throughout during such times as a result of garment production being an exclusive commodity. Personal measurements were taken, and clothing was elaborately relegated to the rich. With the commencement of the industrial and technological revolution, much importance was given to standardized measurements. Ready-to-wear clothing became a trend. However, this was not very easy because a lot of research had to be done to make sure one size fits all of the individuals of that particular size and shape. Till now, there have sometimes been ill fittings caused due to standardized measurements. Dress pattern designing has been a tedious process for ages. The craftsmanship required to create an outstanding design has been a priority for garment designers. The fashion industry relies solely on designing these patterns for different garments, which finally makes an impeccable design.

If you have a style in mind, you can start creating the pattern or the look by creating an associate imprint of the varied items you have got sewn along. The design imprint is the very foundation of a dress pattern design, which is finally assembled into a complete design.

A lot of nations follow measurements such as North America or UK sizes. For shoes, usually, EU measurements scales are followed as well. It depends on which measurements fit you most appropriately.

A traditional cut by the tailor was based on the markings made by chalk. But if you take a look at commercial production, industrial clothing patterns use mass production fit to suit several standard sizes. Blocks of pattern or slopers have been recruited to give impeccable size and fit. Grading is the process where different sizes are made for a finished pattern.

With grading, you can create a line of differently sized garments with similar patterns. Pre-graded garments are sold by a lot of firms, which can be further sewn at home to fit sizes.

Patterns are made by specialized pattern makers available with the firm. They ensure the accessories and garments are assembled by sewers and manufacturers. Each design is examined, and the best way to break down a pattern into a series can be reassembled. You can make paper outlines, prepare instructions in sequence and reassemble the design. Try making notes on the pattern to better communicate with the manufacturing unit. For example, the use of buttons, zippers, hooks, etc.

Pattern making methods

Different methods are used to make patterns. These patterns can be sewn together to form a garment. Two popular types of pattern making are:

- Sloper method/ block method- Flat pattern and Model method

- Computerized Pattern Making with software

Block method- this basic method of garment patterns is a no seam method. It is also referred to as the basic pattern or the sloper pattern. This is the very foundation of a pattern design. A block method is based on either the standard or custom measurements.

There are two methods used which are widely applicable to women's garments:

Flat pattern method:

The method uses a variety of straight edges, measurements, and calculations to pen a draft on paper. The sloper, also known as a block, is a simple plane method design that maneuvers an existing foundation pattern. Then a muslin fabric is used to cut out a draft piece. With comfort and ease, the fabric is fitted to a mannequin or a model.

Changes are marked on the paper draft. The flat pattern-making method is easy since patterns are based on templates that are followed as instructions. The initial steps are difficult as it involves making the templates.

Templates look uncomplicated, but they require multiple fitting tests and human body measurements. They demand perfection as other subsequent dress pattern designs will be based on these.

Once the block patterns are set, there is no need to measure the body fittings. The traced patterns are used to exercise these working patterns, and once these are tested, they become ready for the production line.

- Modeling - Also known as the 'draping on a model' method, modeling involves using a muslin fabric for fitting garments for an appropriate size. A toile is not a neat and clean finished, hemmed garment but is a translucent linen fabric to test whether the garment is being stitched on the designated fits. Each component is transferred into the creative pattern as it provides a clear view of the product, which the designers foresee for dress pattern designing.

Computerized pattern-making method:

Draping can be utilized for computerized visualization of fittings of the garment. Dress pattern designing has been made virtually sound easy with the introduction of computerized designing. The modeling method is also time-consuming, and there are no chances of rectifying mistakes. Computerized software also provides a 360-degree view of your designs.

You can use CAD as it is an easy software and the most advanced method for designing. New design entrepreneurs are using this technology to introduce digitization and improve their designs. Blocks or slopers are also made with the help of software.

A pattern is an interpretation of a dress pattern designing process. Pattern drafting is the process of drafting patterns as the body measurements followed by certain instructions to create a garment style.

Body measurements are converted into a series of straight lines, curves that determine the overall sections of the patterns. These patterns are cut, resulting in a reusable pattern. These pattern pieces have information regarding size, grainline, stitch pattern, marks for buttons and pockets, seams, and hems. This is termed pattern information. They also contain specific instructions regarding the drafting and how to put together the design.

Pattern making and its importance

Pattern making is essential to sketch designs into a garment. This is the basics and a link between the designing process and production. The three major elements of the pattern-making process are interpretation, technique, and technological aspects. These three complete the development of garment pattern production.

The interpretation is the ability to read and understand the design/sketch and its objective. The technical challenges of the interpretation can be resolved by the technician until the goal is accomplished.

The technique of the pattern maker should have a large set of tools. This should be selected while making different specifications to achieve desired results.

A customized production depends upon the technological facts which can be interpreted into the pattern-making design. One should have a mindset to understand the production relevant to the dress design pattern.

The prerequisites for making a pattern, the knowledge, and basics of geometry should be done based on a manual or by the usage of a software.

To sum it up

Dress pattern designing has to be always on point. The detailed steps of the dress designing process enable the garment technologist and production line to set the course of the next anticipated process. If the base is set right, it makes the whole process a lot easier, and it also enables one to judge any forthcoming mishaps during the process.

There is huge scope for pattern and garment technology. Starting right from the designing process to the finish line, each garment has to have standardized measurements according to the firm's desired standards of size and pattern. Each fabric also demands a lot more than just cutting into templates and sewn together. There can be different fabrics that require different methods of tailoring. In case you are naive and require help regarding the technicalities of designs, have any doubts regarding the dress pattern designing process, or if you need help sourcing clothes, connect with Fashinza.