Impact of the Increased Demand for Man-made Fibres

With the change in global fashion trends, the demand for man-made fibres for textiles is spreading all over the world, especially as a competitor to cotton. At present, the global man-made fibre consumption is at the ratio of 72:28, which means man-made fibres account for 72% of the overall textile fibre conception. The natural fibre consumption globally remains at just 28%! This is mainly due to the limitation of natural fibre growth and the demand for versatile fabrics.

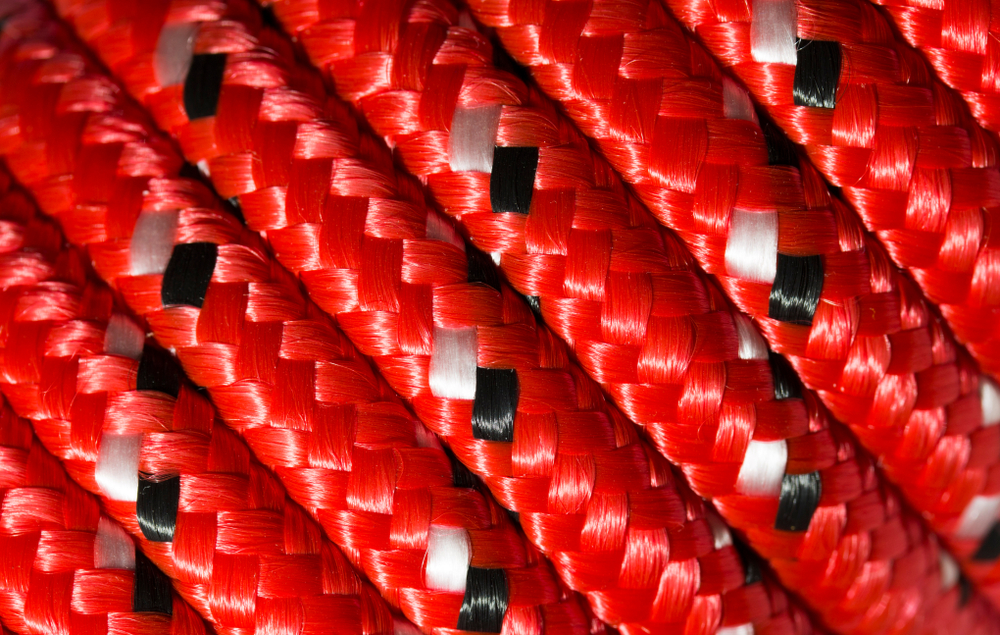

Man-made fibres are divided into two categories, cellulosic and synthetic. Cellulosic fibres are sourced from wood pulp, whereas synthetic fibres are sourced from crude oil. Acrylic, polypropylene and polyester are the most used synthetic fibres, and modal or viscose is the most common cellulosic fibre. Man-made fibres have arisen in popularity in the textile industry over the decades due to their comfort, maintainability, versatility, low manufacturing cost etc.

And according to major reports, demand for man-made fibres is to rocket from 72% to 73%, mainly in developing countries, around Asia.

Furthermore, according to the UN, the global population is estimated to reach around 8.1 billion by the year 2025, thus moving up the demand up to 35% for additional food products. This increase in population is also expected to reduce the availability of cropland, thus limiting natural fibre production. The increasing population also increases the demand for textile fibres, both man-made and natural, by 60%, resulting in even more conception of man-made fibres. This is because the availability of raw materials to produce man-made fibres is available unlimitedly for the next few decades and costs significantly less than natural ones. Another major factor that increases the demand for artificial fibres is that, unlike natural ones, man-made fibres can be recycled, used in research, as well as can be altered to make them suitable for new applications.

These factors do not just increase the demand for man-made fibres now, but in the future as well as in the long term!

Advantages of Man-made Fibres

Man-made fibres are preferred to natural fibres, as they have distinctive characteristics like low making cost and high strength. This has ensured the demand and higher production of man-made fibres in the textile industry. Here are a few advantages of man-made fibres:

- Man-made fibres can be easily washed and retain their original shape even with excessive use.

- They are super elastic, ensuring a versatile use.

- They are cheaper to produce and manufacture compared to natural fibres.

- Incorporating dyes and colours are easy as compared to natural fibres.

- They have high tensile strength and can take up heavy things efficiently.

- They have a soft texture and are perfect for regular clothing purposes.

Impacts of the Man-made Fibre Demand

Cotton Consumption in Various Regions

The demand for cotton fibres globally in 2015 was 24,107.9 KT, and the production was 21,709.5 KT. The demand for these cotton fibres is expected to reach at least 28,054 KT by 2022, growing at a rate of 2.5%. The domestic consumption in India, China and many other South Asian countries, along with North America and Europe, are the major cause of increasing demand for cotton in the Asia Pacific region. Due to this demand, Europe along with countries in the Asia Pacific, have started expanding their textile industry in Turkey.

The prices for cotton fibres globally might remain stable due to stock clearing, and lower prices of man-made fibres due to the crude oil price. However, the demand for cotton fibres is to grow at a slower rate as compared to man-made fibres as the emerging economies gain more from synthetic fibres due to the increasing industrial applications.

MMF Consumption in Regions & Market Share

For the time being, synthetic fibres are expected to exceed the demand for cotton fibres during the next few decades. The demand for synthetic fibres globally is expected to grow at a rate of 3.1%, as compared to 2.5% for cotton. This growing demand for man-made fibres is mostly driven by factors like increasing demand for textiles due to population, limited cotton production, increased application of synthetic fibres to industrial use and high cotton prices.

The demand for synthetic fibres in Africa and the Middle East is to grow at the fastest rate, as there is a large presence of industrial basis, along with a growing textile industry, which accounts for up to 69% of the global man-made synthetic fibre demand. Just for the African and Middle East region, the demand for the fibres is expected to be about 4.1% and reach 52,015.0 KT by the year 2025. The increased adoption of synthetic fibres and growth in domestic consumption can even lead to excess demand than the given numbers.

Both the increasing consumption of textiles as well as the increasing population, along with the limited production of natural fibres, is expected to expand the cellulosic gap each and every year. The only substitute that has favourable properties as cotton is viscose fibre, which still accounts for 37% of the fibres used, containing cellulose properties.

Eco-friendly Man-made Fibres

There are many advantages to engineered fabrics, as the properties can be added and removed as desired. Man-made fibres also have unique properties like the capacity to hold pleats and great absorbency. They are also more durable and can be made in multiple hues, and also be designed to be waterproof, flexible, and stain-resistant!

But along with all these major benefits, the materials used for the production and processing of man-made fibres can leave behind water waste and micro-plastics that can cause havoc for the ecosystem. Keeping this in mind, there are many eco-friendly man-made fibres that are sustainable and meet the demands without causing havoc to the environment. Here are a few examples and their benefits:

- TENCEL LYOCELL

Tencel Lyocell is an ultra-soft fabric that is ideal for individuals who have sensitive skin. The fibre is cellulosic and can be obtained through sustainable and ecological means from eucalyptus plantations and synthesised from wood. During manufacturing, this fibre does not require any harmful chemicals, making the process environmentally safe. It is mostly manufactured using a closed-loop process, where the solvent and water used for the processing can be recycled up to 99%.

Benefits:

- As eucalyptus only grows on dry land, it is impossible to grow other crop plants there.

- Irrigation water is not required to cultivate the raw material.

- The fibre is easy to wash and dye.

- It has excellent moisture management.

- It grows without any pesticides or insecticides.

- It is inherently eco-friendly.

- Recycled Polyester

At present, polyester fibre is produced from recycled bottles and is ideal for re-channelling the chemical polyethylene terephthalate, which is the main chemical component of PET bottles. PET bottles and polyester both contain these chemicals, and recycling them to create polyester fabrics uses a lesser energy source and has shown to be super cost-effective. This process works by depolymerising waste PET bottles using glycolysis, which yields polyester polyglot. This is then processed to have superior qualities like impact resistance, scratch resistance and flexibility, which are finally extruded into yarn.

Benefits:

- Recycling polyester lowers the environmental impact.

- Reduces plastic from landfills.

- Prevents the used plastic from ending up in water bodies and harming marine life.

- Reduces the use of virgin petroleum for raw materials.

- Bamboo Viscose

This is the most popular material used to manufacture clothes these days, as the fabric feels good on the skin. This fibre is a more sustainable alternative to polyester and cotton, as it is sourced from plants and trees, like bamboo, which makes it biodegradable. The viscose fibre can be produced using a close loop system, in which the harmful chemicals are collected and reused as opposed to being let out into the environment. As bamboo is one of the fastest-growing plants in the world, it does not need a lot of pesticides or chemical fertilisers and is available in ample amounts.

The transformation process of viscose requires the use of certain chemicals in-order to transform the bamboo pulp into rayon.

Benefits:

- The clothes designed with viscose are wrinkle-free.

- They are super comfortable and soft

- 100% biodegradable

- Bamboo absorbs 35% more carbon-dioxide

- Bamboo provides an optimal fibre yield per acre

- Does not require any irrigation water, insecticide or pesticide.

Conclusion

The global demand for man-made fibres is expected to witness a growth of 2.7% this year, due to limited cotton supply, along with other factors like low prices of man-made fibres and increasing consumption for home textiles and industrial applications.

If you own a textile business or are looking to start a new one, keeping up with the manufacturers and finding vendors to source quality man-made fabrics can be a hectic job, given the demand.

This is where Fashinza comes in! Fashinza offers end to end production management, from finalising your designs, assessing the best selling MMF to production, quality check and prompt delivery. Contact Fashinza today and launch your exclusive collection of quality apparel!