Quick Guidebook For Clothing Pattern Maker

What is pattern making?

Pattern making is the process of creating a clothing design. To design a garment, cut out the cloth that meets the stated specifications using the pattern. The type of material, the wearer's ideal fit, and the trimmings used should be taken into consideration. The purpose of the plan is to ensure that this 2D fabric is properly placed in the 3D body.

Tools needed for pattern makers

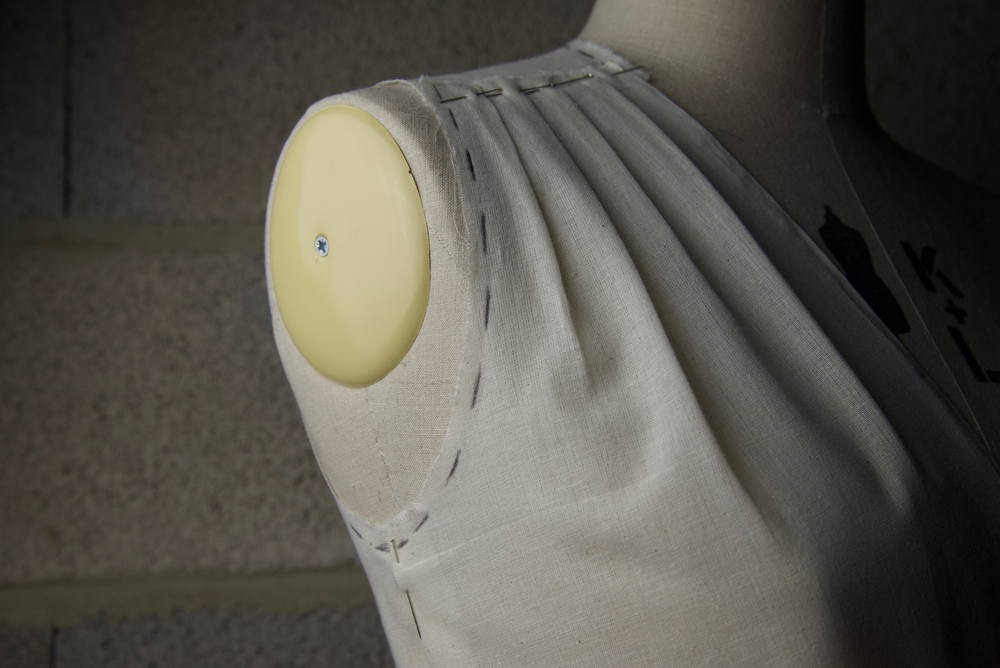

- Draping and patterning are the most common forms of patterning. Each approach requires slightly different tools to complete the task. Drape is done by manually twisting the fabric of the dress form to create the desired look.

- You will need a dress form, cloth, needles, paper pattern, French curve, and straight ruler to get started.

- Wrap the material around the shape until it has the desired shape and give it a mark to give it a shape. Then the material is removed and spread flat. French curves and rulers are utilized to straighten the line. After that, the cloth pattern is copied to pattern paper. The pattern is then modified by adding seam allowances, notches, and other appropriate markings.

- Drapes frequently require detailed folds, yet they are costly and inaccurate when compared to flat designs.

- A flat pattern is generated on a flat surface, as the title suggests. Manual flat patterns are made with pattern paper, a French curve, a straight ruler, and a pencil. The drafting techniques for generating flat designs are the same whether done digitally or by hand.

What approach does one use to calculate your frame measurements?

It is vital to apply unique frame measurements whilst creating a well-becoming clothing. But how can one decide what frame measurements ought to be? It all relies upon the wearer.

Making a custom designed garment for any person is largely to make use of the remaining wearer`s actual frame measurements to make the sample. To report all the required measures, use a dimension sheet.

But what creates mass-marketplace clothing? A greater wide frame dimension is required. One can discover ok physical information in a whole lot of techniques to get the styles required. ASTM frame data is a combination of the numerous frame scans that can be received from a whole lot of suppliers. Other information experts, like Alvanon and Human Solutions, can also help in tailoring the frame information to their precise goal marketplace.

What is a basic pattern?

A simple design, often known as a block pattern, is based on body proportions and merely has wearing ease. They are required to ensure that the fit of a brand is consistent. When it comes to fit, consistency means that customers can buy their size with confidence, knowing that it will fit. The simplest method to gain this confidence is to use a simple pattern library as a starting point for all design patterns. Customers will get patterns with only the necessary seams for fit and, as a result, the suitable amount of wearing ease for the textiles they're created for with a good basic pattern collection. Design ease, extra design lines, and other design aspects will be incorporated later at the fashion level.

Creating a pattern that's ready for production

- Getting the pattern right

Trueing the pattern is the first stage in completing the pattern. This includes checking that the seam lines on each section are the identical length because the seam lines on the piece to which they'll be attached, which there are not any odd angles at the highest or bottom of the seams.

- Exceptions to the rule:

There are always exceptions to any excellent rule. If the garment has pleats or darts, the sting of the pattern piece with the darts/pleats is longer than the sting of the pattern piece without. Close the darts/pleats as they'd be if they were sewed, and so walk the pieces to verify the seams are trued.

Another example is the sleeve shoulder cap. so as to confirm optimum mobility and shoulder rotation for the wearer, a shoulder cap is often slightly longer than the armscye to which it's sewn.

As a result of the character of the planning, things like gathers, extremely curved design lines, and then on may have a variance in pattern edge lengths.

- Drilling holes, notches, and marks

During the sample making and manufacturing process, notches, markings, and drill holes are accustomed to show a range of things. Notches are carved into the material and accustomed to align certain seam lines or show where two items should be matched.

Notches are wont to highlight where the highest of a side seam vent may well be put, also as one notch on the front armscye and front sleeve and a double notch on the rear armscye and back sleeve. All of those are there to guide with the stitching process.

Notches are accustomed to align rib collars, which are cut smaller than the neckline to which they sew, so the garments are often stitched uniformly. The collar length is simply about 85 percent of the length of the neckline. The notch indicates where the shoulder seam should be aligned in order that the collar is stretched equally before and back.

Within pattern making, marks can talk to a range of things. One can have marks that show where a button or a snap should go, where a graphic or logo should go, where a pocket should go, and so on. Marks are made on the material, but they're not cut. The rectangle mark displayed here is for screen print placement, in order that the garment is correctly positioned before printing.

Drill holes are yet one more crucial pattern indicator. They seem to be a little hole accustomed to displaying details like the corners of a placket. The Henley button would be placed on the look with the corners drilled as holes while extirpating the look piece for a Henley collared shirt, as an example.

- Grainlines

Grainlines show how the patterns are going to be displayed on the material to be cut. This must be clearly stated on the pattern so as for the material to be cut appropriately. The grain has a control on how a cloth drapes and stretches, likewise as how a print or nap will seem when cut. Grainlines are commonly marked by a line running the length of the pattern piece. The grainline in digital patterns determines how the components are placed in an exceedingly marker.

- Including the seam allowance

Next step is to feature seam allowance (commonly abbreviated as SA) to the pattern now that it's been trued, marked, and notched. The material that may be accustomed to stitch the garment together is understood because of the seam allowance. The number of seam allowance required varies irrespective of the kind of seam, the sort of sewing to be used, whether a seam is going to be bonded instead of sewed, and other factors.

- Developing a marker

This isn't a sketching instrument. The marker could be a phrase utilized in the apparel pattern industry to explain the layout of a pattern for cutting. Within a marking, the parts should be matched down the grainline, with a little buffer of space between them to stop one piece from cutting into another, and ideally want to try and do everything one can to optimize how the pieces are laid together for max material yield and minimal waste. To think about marker making as a grown-up version of Tetris. Better to arrange the parts to spend the cash less and there'll be less wastage of fabric. Using around 77 percent of the material, with the remainder visiting waste.

Raising the usage to just about 85 percent by rearranging the parts in an exceedingly more ideal configuration, saving money on fabric prices and keeping more of our fabric out of landfills.

- Getting the fit right

Having a fitting after finishing the pattern and stitching the primary sample, It's possible to form some tweaks to the fit. There are a spread of reasons why a pattern might not be right the primary time. Things just like the drape of the material, any shrinkage which will occur during the sample's manufacture, differences within the wearer's dimensions from the drafted body, and so on.

The most common changes are bust adjustments, which are especially popular on woven clothes, to make sure that darts hit within the right place. Shoulder slope, rise form, and neckline alterations also are popular fit adjustments.

All of those things are a part of the quality pattern-making process, and that they may be tweaked on your designs once they have been fitted.

For more information, visit the official website of fashinza.