Globalization and the Global Textile Industry's Production Scenario

Globalization is a multidimensional word with a lot of depth, and aspects that can be clearly understood only if one looks beyond just the immediate impact measured. Globalization by textbook definition refers to a network of trade and commerce between different economies of the world brought together with sharing of goods, culture, services, investment, labor, and technology.

Globalization has seeped into economies, cutting across borders and all industrial barriers as well. It enables a person in the cold and desolate parts of Russia to get goods from Brazil along with customer care from a guy in India through an American shopping platform. This is a true example of the potential and power of globalization. The world is taking steps towards inclusive growth and development, making way for a global village-like scenario. No sectors of a nation's economy have been let off by this growing change, including the textile industry. Like every other revolutionary change in history, globalization holds its benefits and losses.

Changes brought about by globalization to the textile industry are both diverse and also adverse to some extent. For example, while the innovative technologies invented through sharing knowledge have increased the efficiency and quality of fabric produced, it has rendered thousands if not millions of manual laborers unemployed.

Impact of globalization

Globalization's influence may be seen in several aspects of the textile industry, beginning with brainstorming ideas for delivering high-quality items throughout the world. The influence might be observed in a variety of areas of the business, including demand, fabric kinds, fashion trends, and the creation of hi-tech and environmentally friendly materials. Globalization has had a favorable influence on the lives and living conditions of those who work in the textile sector in this aspect.

Outsourcing

Outsourcing is a characteristic of globalization-affected sectors. Organizations from a variety of countries, the majority of which are developed, outsource their production, advertising, and other units or jobs to smaller but efficient companies from the same country. Because there is such a significant currency disparity between the countries, this is a considerably more cost-effective form of large-scale production. Many times, businesses perform their tasks for half the cost they would have paid before globalization.

Business tycoons in the textile industry have attempted to deconstruct their production process into minor processes based on needs and requirements in order to reduce their expenditure while still reaping the benefits of selling high-quality products. They do so by locating production units or awarding contracts to small local businesses. Multinational corporations from rich countries are launching a slew of similar partnerships in poor countries, lowering production costs while maintaining profitability and product quality.

Research indicates that more than four million job opportunities have been provided in developing nations like India, the Philippines, and China. Furthermore, jobs are still to be deployed from developed, superpowers nations to economies that are expected to be on the rise shortly.

Because of the advantages of outsourcing, many new MNCs have begun to seek clients from all over the world rather than only inland natives. Many emerging countries, including the Philippines, Vietnam, Bangladesh, Myanmar, Brazil, and Africa, are putting pressure on Indian and Chinese labor markets.

Low currency, high competition

Nations with lower currency value are being preferred for outsourcing work as they offer prices lower than that of India and China, as well as the developed countries. Due to heavy competition for outsourcing ventures among developing nations, corporate giants get their production work done at low prices with the same quality.

Due to a severe struggle for economic development and survival, commercial company bigwigs make use of the amenities supplied by emerging countries. The concept of manufacturing units has piqued the interest of the fabric world. Leading fabric producers forced people from other countries to labor for little pay and in deplorable circumstances.

Harsh reality of textile globalization

Workers were refused the compensation they required to maintain their families and communities, despite laws protecting their rights. They were repeatedly exposed to identical working circumstances, which had a long-term negative impact on their health.

Commercial businesses relocate their operations from their own country to emerging markets. As a result, people in their native nations lose their jobs. The residents of wealthy nations do not have a choice. According to statistics, the United States has lost more than 5 million industrial jobs since 2000. Fabric exports from the United States fell to their lowest level in ten years in 2007. The number of people employed in this business declined by 9.2 percent.

Through outsourcing, large businesses engage in unethical and irresponsible practices. There are few international regulations that oversee such acts. Commercial houses continue to make money at the price of job opportunities in wealthy nations and a decent wage for workers in underdeveloped countries. This discredits the two countries' sustainable way of life. Several times, in the name of free commerce, comparable conditioning has been hampered.

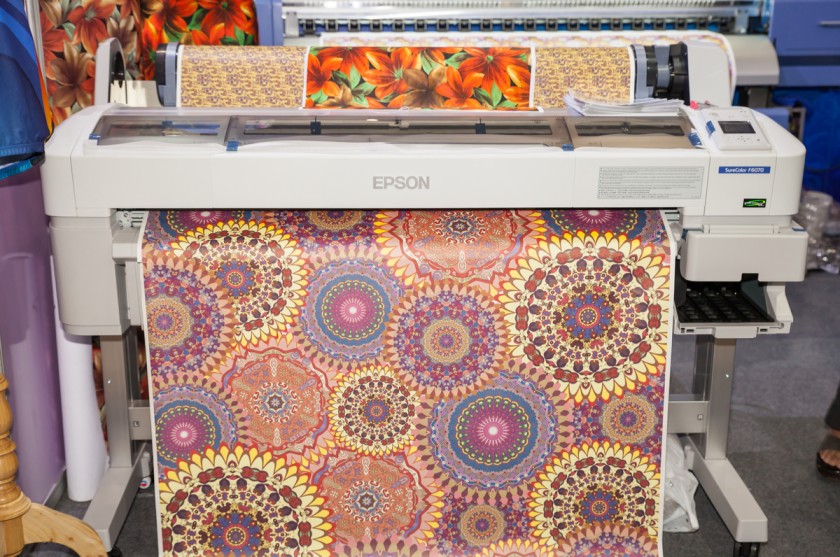

Fabric printing

Another aspect of globalization apart from outsourcing is the rise of new technologies such as fabric printers, which have led to a large-scale lay-off of manual workforce from the global textile industry. The industry previously relied entirely on manual laborers for creating designs on fabrics or even dyeing the cloth with desired colors.

The wide variety of fabrics available nowadays is immense, right from natural fabrics like cotton, organic wool, or silk to artificial fabrics made using polyester, polyamide, and other chemically treated fabrics. The diversity in nature of the fabrics, as well as intricacy of designs, have always been convened by new designs swayed by various garments and costly designer works, which gave rise to the far-reaching textile industry that is in operation. The fast-moving fashion industry exploits not only the fabric variety produced by the textile industry but also the cloth printing possibilities, which weren't always readily available in the past without the modern fabric printers.

History of textile printing and effects of globalization

The proof of textile printing was found in China and among the Incas in Peru during the first century. In Europe, patterns on fabrics made using manual fabric printers were introduced much later due to the difficulty in achieving durable printing, which doesn't fade or wash off. It wasn't until the development of durable dying stuff that enabled the first printing of patterns on fabrics to be made.

The original system used was rather primitive and done by hand. The technique of woodblock printing involving a pattern engraved on blocks used to print designs was the first attempt to create patterns on cloth, and it's still employed at the moment in some places in India and Asia as fabric printing in its most primary form.

Modern breakthroughs

A successful attempt to print fabric using machines was made much later by making use of intricately engraved rollers to print designs on the fabric. This was a revolutionary step in the development of modern-day fabric printers.

Even though this was a breakthrough for the textile industry and its capitalists, this meant trouble for its workforce. After introducing mechanical fabric printers, a large part of the manual workforce was let go due to the lesser need for man force when creating textiles on a large scale at cheaper prices using the fabric printers.

With mass production now made simple and easy, the capitalists that we're able to employ the use of mechanical fabric printers showed no interest in returning to a labor-intensive mode of production.

There was also a huge difference in the amount of fabric that was printed on using the printer and the work done by the manual workers. The fabric printer was easier to handle and created uniform goods with not much deviation in quality, and generated an enormous amount of output in less time. This was something the human workforce could not achieve. As the market changed and demand for machine-printed fabric grew, so did the innovations on fabric printers.

In recent years, there has been a great increase in demand for fabric printed with patterns using fabric printers that the producers were unable to meet with the use of regular printing techniques. Soon, the accelerating rise in technology delivered another breakthrough, called a digital printer.

Digital printers

The digital printer, after many improvisations and hurdles, managed to offer a feasible solution to all the problems that, until then, came with the use of such printers, which were previously not suitable for fabric printing. After many adjustments like changing the printing heads and the type of ink used for each type of fabric, it became suitable for the fast, mass production of printed fabrics.

The new textile printers are still in need of many changes and improvements, but they remain a vital force in the production of not just regular printed fabrics but also personalized ones, greatly affecting the production aspect of the modern global textile industry.

Conclusion

The globalization of all the different industries, along with the world at large, has caused many changes in the production techniques undertaken in the textile industry. New methods of production and technologies were introduced and invented to increase the ease of production and also to add diverse features that help round up consumers. The premium features adopted by the textile industry include outsourcing of production and innovative fabric printers, which opened new ways for development.

Stay in touch with Fashinza for more such fashion industry updates and trends, while also finding optimum digital fabric printer designs and manufacturers for your business.