Basics of Apparel Plant and Sewing Machines Layout

Introduction

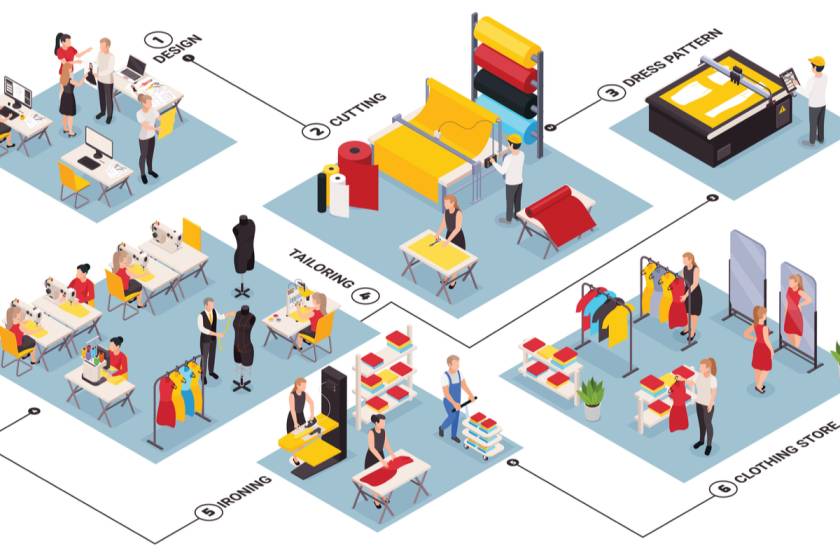

The layout of a garment factory is associated with a good workflow which includes things such as receiving materials and sending the finished goods out of the garment factories. Therefore the type of apparel plant you develop directly must be optimized according to time and flexibility. There may be slight changes according to the owner of a garment factory. However, there are some common things that you must keep in mind before making a blueprint and proceeding forward.

Now let's talk about a plant layout. An apparel plant layout is the management of space and position of various departments, machinery, and working areas necessary for the functioning of a plant. The layout must be such that the plant will have a good workflow, and there must be integration starting from receiving materials to producing finished goods and sending them to the market. Apart from all these, you must make the layout of the garment factory in a way that it will be flexible enough to change depending on the requirements or the demand of the product, delivery schedule, etc. You must also involve things in the layout such as emergency exits, fire, and safety areas, etc.

Here are some factors which you must keep in mind before planning a layout:

- Keep the cost of manufacturing low.

- Plan the layout in such a way that the feeding of materials to the machinery must be speedy. It must also be ensured that none of the parts must come back.

- There must be room for the plan, including revamping the factory.

- Keep fixed and properly allocated places for all the pieces of machinery and work processes.

Garment factory's layout

Make the layout of the garment factory in such a way that the steps involved in the production of an item, building structure, and the configuration of machinery are followed properly. Some factors which have an impact on the layout of a factory or plant are:

- The number of workers, both male and female

- The number of machines

- The placement of entrances and exits

- The location of the administrative office, changing room, washroom for both men and women, medical emergency rooms, etc.

Steps to Make an Apparel Plant Layout

- The first step to making a good layout is that the layout must be properly scaled without any rough estimates.

- Make models of the machinery.

- Draw the immovable equipment which will be permanently fixed in a particular location.

- Mark things such as entry points, exit points, washrooms, corridors, vacuum lines, air conditioning ducts, etc in the layout.

- Other crucial things that must be included are power sources, electric lines and water sources.

Try to incorporate everything related to the process according to the production flow in a straight line.

Factors That Impact the Layout of Machines

Let's know what the machine layout is. Machine Layout is an arrangement based on the sequence of the operations. Here are some factors that you must keep in mind before setting up the machinery layout -

1. Products to be manufactured

Before making the layout of machinery, the types of products to be manufactured must be kept in mind. Along with the type of products, man-hours, the different types of apparel, designs, and changes in fashion trends every year are things that you must also consider before setting up the layout.

2. Manufacturing system

The manufacturing system must be according to systems such as PBU assembly line, sectional assembly line, etc.

3. Method for alterations in style

There are two types of changes: overall change and consecutive change. Overall changes occur when the products being manufactured are not associated with each other. Therefore if some changes have to occur, there will be an overall change. In consecutive changes, manufactured products have much more similarities and have negligible variations. Most of the operations required to produce these products are similar. Hence, major changes are not necessary.

4. Material transfer system

a. Bundle system

In this type of system, the products are packed in bundles which can be in a bundle of 5, 10, or 15. The size of the bundle is also important as it will impact the way it will be handled. Usually, these bundles are packed in boxes.

d. Per piece

Per piece, transfer means that the parts of a garment are moved from one operation area to another one by one.

c. Overhead hanger

The parts of the garment are clipped in hangers which present overhead and can be moved by rails manually.

5. Storage method of semi-finished goods

The layout should also be made keeping in mind the places that can be used to store semi-finished products.

6. Equipment

The equipment includes types such as machines that are used for special purposes, general-purpose, semi-automatic, and automatic work areas.

7. Transportation equipment

The equipment for transportation includes

- Manual transportation

- Racks

- Trucks

- Conveyors (powered and unpowered)

Conclusion

This is how you can create a layout for both your plant and sewing machine layout. These tips will be helpful for those that are new to the fashion industry and are in the process of setting up their first apparel plant.

In case you are a designer and need a platform that will help you manufacture your designs, look no further as Fashinza is here to cater to all your needs. As a customer you just need to place an order with them and the rest will be assured by them. The most convenient of all things is that it takes care of all things starting from design to delivery of the products. Fashinza makes it hassle-free, safe and transparent for you.